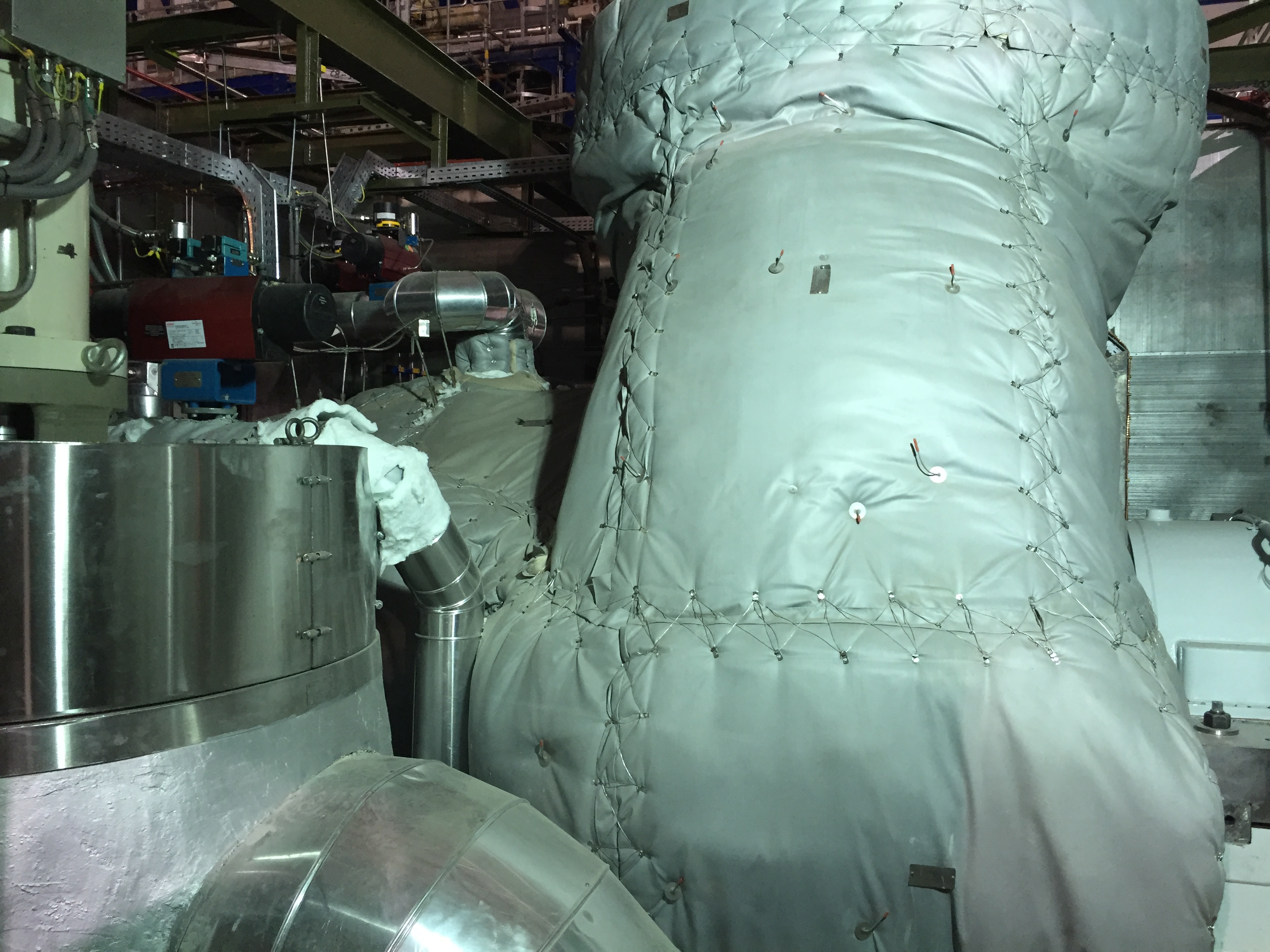

Astaş Insulation Jackets

Astaş insulation jackets are made using heat

resistant fabrics and insulation materials with low heat transmission

coefficient. Produced in factory or which are custom-built depending on the

area where the application will be made, these products are covered outside the

machine or equipment so as to prevent heat loss from surface.

In periodical maintenances, insulation

jakcets are dismantled so help finishing the maintenance easily. These

products, of which assembly and disassembly are very simple, prevent the

machine from working rapidly and thus also prevents an extra cost. These

applications continues to provide energy saving in plants without losing their

quality for long years.

Range of Application of Astaş Insulation

Jackets

• Turbine Casing

and Lines

• Marine Exhaust

Lines

• Marine Boiler

Rooms and Lines

• Engine and

Generators Exhaust Lines

• Machinery,

Equipments and

Lines

• Boiling Oil &

Vapor

Lines

• PowerPlants

• Heat Exchanger

• Vessel

Surface

• Textile Dye Machinery

The Advantages of Astaş Insulated Jackets

• High temperature resistant.

• Easy to pull out and to fasten.

• Can be used repeatedly.

• Very low cost of assembling.

• Non- Burnable.

• Easy to use in narrow areas.

• Long lasting.

• Makes equipments life longer.

• Do not include asbestos and

cancerous substance.

• High quantity of energy saving is

made by heat insulation.

• Prevents combustion on cooling

systems.

• Supportive to fuel steam.

• Supportive to atmosphere

conditions.

• Supportive to oil, water and poor

acids.

Manner of Application of Astaş High Heat Insulation Jackets

These manufactured cushions are put side

by side and piled one on top of another like jackets a machine and they are

wrapped all around the machine and heat leakage from anywhere is prevented. A

machine that is insulated in this way becomes ready to repair thank to easy

disassembly of cushions on the occasion of periodical maintenance or repair.

After required repair is done, cushions can be assembled to their places again

and the machine become ready to function in a very short time. Correctness of

the application should be reported with the thermal image to be taken after

application.